6061-T vs 6063 What’s the difference . Know what you are buying

First this isn’t to ‘slam’ anyone’s choice of who makes what and why you bought it. This is blog post is to state the simple facts of grades of Aluminum and types of aluminum manufacturing process.

Most aluminum aftermarket parts are ‘billed’ as 6061 aluminum and CNC finish. You see this in almost every description of every manufacture of parts. Then they also add in Forged or Cast or my favorite is Billet. As if Billet makes it better cause if sounds ‘cooler’.

Since we manufacture parts in house we have great knowledge on aluminum, their properties and manufacturing process.

Here is some food for thought before you get shell out money for something (lets says a Grom stretch kit) that has a same look of something on Amazon that cost $79.99.

There are reasons that $259 dollar parts cost more than $79.99 parts. You start with a grade of aluminum. A machine rolls, forges or cast the aluminum. A CNC machine finishes out the product. Chinese machines are not cheaper to operate than US machines. We can argue that the Chinese person who puts the metal into the machine gets paid cheaper, but time for each machine to operate the process is the same unless it’s a cast product. The Chinese machines do not work fast. Do the Chinese work on razor thin margins and that’s why their is such a drastic cost difference? No. The price is difference is mainly material.

Lets look into grades of 6061 aluminum:

First many claims 6061 aluminum. Some put -T6 at the end. What is T6? Is their a T ‘less than 6’? What does this mean? Below are what grades of aluminum we use and what we have seen from other companies. This information is from Wikipedia.

From Wiki:

The mechanical properties of 6061 depend greatly on the temper, or heat treatment, of the material.[3] Young’s Modulus is 69 GPa (10,000 ksi) regardless of temper.[4]

6061

Annealed 6061 (6061-O temper) has maximum tensile strength no more than 120 MPa (18,000 psi), and maximum yield strength no more than 55 MPa (8,000 psi). The material has elongation (stretch before ultimate failure) of 25–30%.

6061-T4

T4 temper 6061 has an ultimate tensile strength of at least 210 MPa (30,000 psi) and yield strength of at least 110 MPa (16,000 psi). It has elongation of 16%.

6061-T6 ( THE RUCK SHOP PARTS WE MANUFACTURE USE THIS)

T6 temper 6061 has an ultimate tensile strength of at least 290 MPa (42,000 psi) and yield strength of at least 240 MPa (35,000 psi). More typical values are 310 MPa (45 ksi) and 270 MPa (39 ksi), respectively.[5] In thicknesses of 6.35 mm (0.250 in) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties. The typical value for thermal conductivity for 6061-T6 at 25 °C (77 °F) is around 152 W/m K. A material data sheet [6] defines the fatigue limit under cyclic load as 97 MPa (14,000 psi) for 500,000,000 completely reversed cycles using a standard RR Moore test machine and specimen. Note that aluminum does not exhibit a well defined “knee” on its S-n graph, so there is some debate as to how many cycles equates to “infinite life”. Also note the actual value of fatigue limit for an application can be dramatically affected by the conventional de-rating factors of loading, gradient, and surface finish.

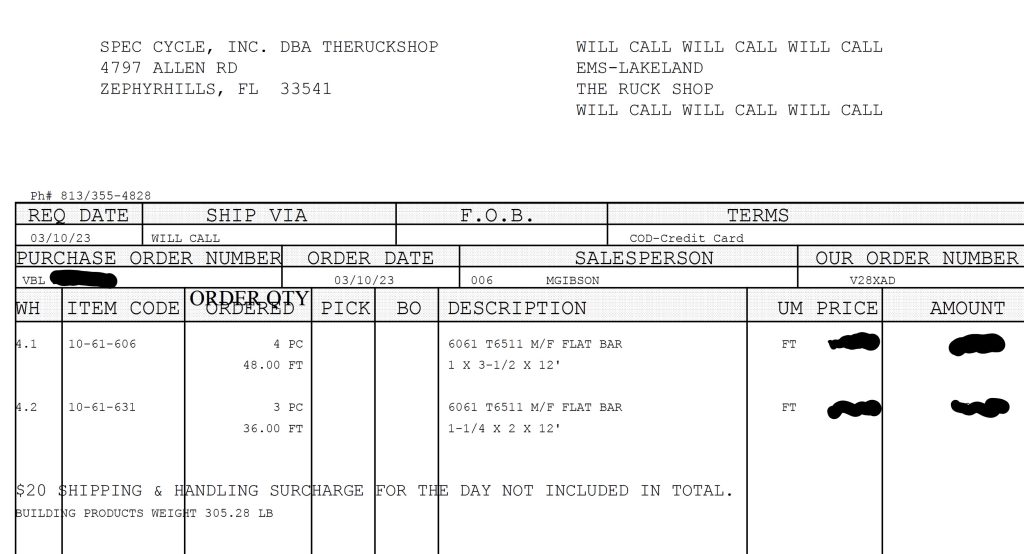

Sample of a reciept below from the material we purchase using 6061-T6. We also get certifications emailed to us.

6063-O

Un-heat-treated 6063 has maximum tensile strength no more than 130 MPa (19,000 psi), and no specified maximum yield strength. The material has elongation (stretch before ultimate failure) of 18%.

6063-T1

T1 temper 6063 has an ultimate tensile strength of at least 120 MPa (17,000 psi) in thicknesses up to 12.7 mm (0.5 in), and 110 MPa (16,000 psi) from 13 to 25 mm (0.5 to 1 in) thick, and yield strength of at least 62 MPa (9,000 psi) in thickness up to 13 millimetres (0.5 in) and 55 MPa (8,000 psi) from 13 mm (0.5 in) thick. It has elongation of 12%.

6063-T5

T5 temper 6063 has an ultimate tensile strength of at least 140 MPa (20,000 psi) in thicknesses up to 13 millimetres (0.5 in), and 130 MPa (19,000 psi) from 13 mm (0.5 in) thick, and yield strength of at least 97 MPa (14,000 psi) up to 13 millimetres (0.5 in) and 90 MPa (13,000 psi) from13 to 25 mm (0.5 to 1 in). It has elongation of 8%.

6063-T6

T6 temper 6063 has an ultimate tensile strength of at least 190 MPa (28,000 psi) and yield strength of at least 160 MPa (23,000 psi). In thicknesses of 3.15 millimetres (0.124 in) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%.

Now lets talk about the 3 process for aluminum manufacturing. Cast, Forged and Billet. These words are thrown around as if there is some magical properties between the three. What are they really?

Cast Aluminum:

Cast aluminum usually refers to the method of forming a part by using a mold. By pouring molten aluminum into a ‘part shaped’ mold, the part is formed when the aluminum solidifies. The casting is then removed and a CNC machine is used to finish the manufacturing process. You can usually tell a cast product because there are casting lines in the product that the CNC machine cannot cover up or removed.

By using a casting process the manufacturer can offer a functional and economic part. (the most economical process of the three) This process can also offer the best synthesis of mechanical properties when A380 aluminum (less pure aluminum) is used during the casting process.

While there has been less than ethical manufacturers who became known for their poor casting processes, if the part is cast properly and attention to detail is adhered to, a cast part will provide quality and reliability for most applications.

Billet Aluminum:

When a manufacturer refers a part being manufactured from billet aluminum, they are usually referring to a part that has been machined from ‘bar stock’. The ‘bar stock’ is formed by extrusion or in other words, from being rolled into a particular shape and size. A piece of the extrusion is then used by the manufacturer and machined on a CNC machine into a functional part.

Billet aluminum parts are considered to be the best looking parts. Due to the ability of the CNC machine to mill fine lines and particular designs, billet parts are known for their aesthetics. While looks do little for overall performance, some like the added ‘cool factor’ to the part. They are usually the most time consuming parts to manufacture based on the other two processes.

Forged Aluminum:

Forged aluminum refers to a part that has been ‘hammered’ into forging dies to shape the aluminum into its specified contour. The aluminum is subjected to repeated force, which in turn ‘forges’ the shape of the part. Once the forging is complete, the part also is finished on a CNC machine.

A forged part is the strongest of all parts. Metallurgists agree that the forging process results in the aluminum having continuous grain characteristics, which results in the part becoming stronger than billet or cast aluminum.

As an example the time to complete a average Forged aluminum AR-15 receiver is 15 minutes vs. a Billet aluminum AR-15 receiver which takes 45 minutes. (see where cost comes in)

There are also tolerates to the cast, forge and billet process. If a cast has air pocket in the aluminum there can be weak points in the finished product. The same goes with bar stock billet or forged if the base metals were faulty to begin with. If the cast mold is worn out there can be loose tolerance differences in the part over time.

We have seen parts from China stating billet but no grade, just the word aluminum, 6063, 6063-T, Aluminum alloy and their variations using the word “aluminum”

CNC Milling Process

Now lets move to the CNC machining process. While these are computer controlled and one would think that they are all the same they do need to be maintained, tools heads need to be replaced and kept sharpened. Then there are total number of CNC process to a part. Skip a ‘for looks’ hole here and there. Have the machining be less sharp to detail. These all cut machine time and cost down.

Finally there are other parts used in the “China Knock off” finished product. They might use very cheap springs, cheap stainless bolts, bearings, and others compared to USA manufactured parts NOT sold from a USA company. Many American companies sell Chinese Knock off parts. Just because a part is sold from a company in USA doesn’t mean it’s better. We too sell Chinese parts. But we are talking about a part MANUFACTURED in USA vs CHINA. This is not a bad thing. You just have to know what material each party is using. We will get into this more below.

So why would there be a difference of a $259 USA part vs. a $79.99 eBay/Amazon special?

Well simply put they are typically using lesser grade aluminum, usually forged (even cheaper if cast) and finished with less CNC machine cuts. The additional parts used to finished the final part are cheaper grades and quality. Now add in the cheaper labor guy for the forge/cast process and the guy who runs the CNC machine and there you have it. Does this mean its a bad part…..No…Could Be…..Yes….. It’s really hard to know from a picture and “opened the box and it looks great, buy with confidence” reviews.

So would I personally trust the eBay or Amazon advertising that a say CRG ‘knockoff’ levers are the same as the CRG manufactured lever? I mean they clearly state in the advertisement 6061 or maybe just alloy aluminum and finished with CNC machine……NO. The drastic cost difference is made up somewhere…..only you can guess what corners they cut to get to that price. But the pictures look so…..good.

(In all honesty we deal with Chinese/Tawain/India manufacturing especially for GY6 motor parts we have to watch the shipments and test quality. There have been multiple times that we’ve rejected shipments for not meeting spec. They knew it and tried to pass it along. Sometimes parts fail, can you call Ebay, Amazon and talk to someone or better yet talk to the manufacturer. Not on your life. Can you call us? Yes and we actually have a business phone number.

So does this mean that the less expensive eBay/Amazon ‘knockoff’ parts are bad…..NO. They can be good. It all depends on the grade of aluminum, quality of the CNC finish and quality of the anodizing finish. But, how do you now from a eBay/amazon picture? The problem is these parts are mass produced. they are not from the same manufacture (the guys selling them on ebay or Amazon to you are brokers and not manufactures) from batch to batch. The aluminum grade and CNC tolerances are the same from batch to batch. We even see this on China Brand names we by direct from. Your only real way to tell is to hope the reviews are for the batch your part came from, long term use review and actually a truthful review. Then you can always say, “The hell with it”. For that price…”what the hell?” It’s your life not ours when riding a scooter or motorcycle going 40-80 mph down the road.

We also don’t know if the US/Europe made parts are going to be good either, but it’s much easier to deal with customer service from a name brand supplier rather than a import/export company who translates their response with Google translate. As we stated above. You can call us. We do know what we make and what material we use and our machines are right here in USA.

I don’t want to trust my life on $179 dollar savings. BUT…..that’s just me. Lets face it was have all bought cheap ebay/amazon parts online. Usually they were simple machined, non moving parts. Chinese ‘knockoff’ iphone accessories are quite good. Their ‘knockoff’ 3M Labeled adhesives patches….not so much. Again you got to make up that price difference somewhere.

The real point of this thread is to say don’t be suckered by cheap cost and good photography. Also do be suckered by ‘the most expensive is the best’. It’s all about grade of material, type of manufacturing process and final finish when it comes to ‘knockoff’ Chinese metal parts.